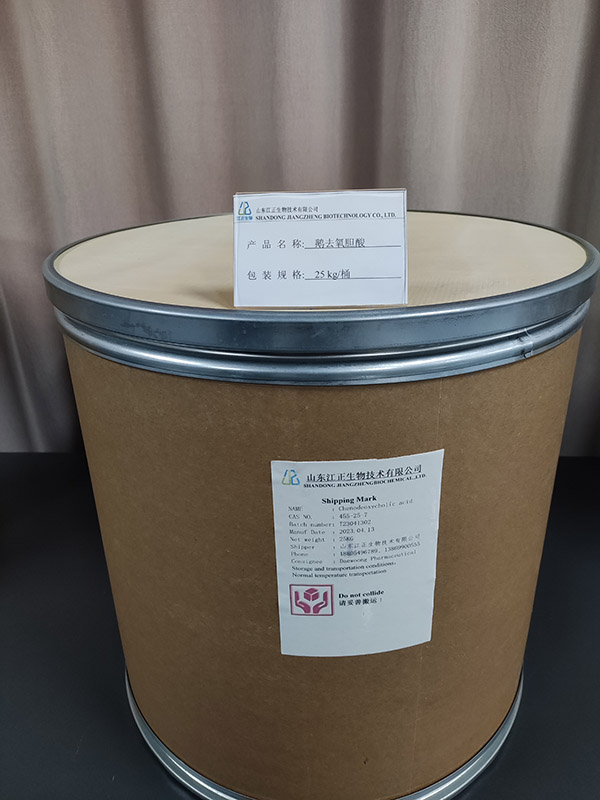

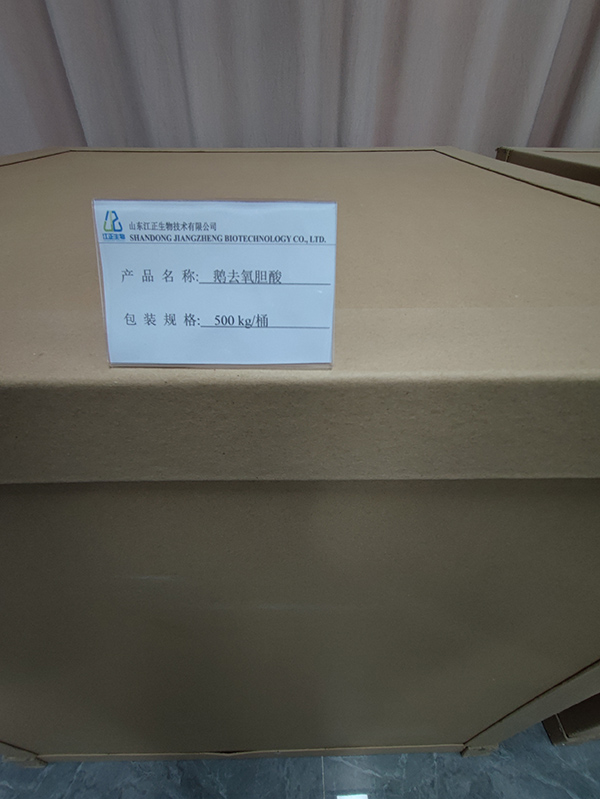

The process characteristics and industry prospects of ursodeoxycholic acid

Goose deoxycholic acid is the raw material for preparing ursodeoxycholic acid. In the process of preparing ursodeoxycholic acid using goose deoxycholic acid, ursodeoxycholic acid is oxidized to 5 by its 7-position isomer goose deoxycholic acid β- three α- Hydroxy-7-carbonyl cholanoic acid (7k-lca), further synthesized. In existing technology, due to the presence of two hydroxyl groups in the structure of chenodeoxycholic acid, theoretically one or two of them will be oxidized during the preparation process. And technical personnel in this industry usually use substances such as NBS, PCC, and chromium trioxide to oxidize chenodeoxycholic acid, and use metal sodium or PD/C catalytic hydrogenation to achieve the reduction of 7-keto cornerstone cholic acid (7-KLCA). In existing technology, although the above oxidation method achieves the goal of oxidizing the 7-position hydroxyl group, it also oxidizes some 3-position hydroxyl groups. Due to limited research in this field on the individual oxidation of the 3-position and 7-position hydroxyl groups, especially the individual oxidation method of the 7-position hydroxyl group, although literature has reported the use of NBS to oxidize CDCA in acetone and water to produce 5 β- three α- Hydroxy-7-carbonylcholic acid (7K-LCA) with a yield of up to 89%. However, the final purity is not high, and there are also some cases of two products being oxidized simultaneously in the oxidized finished product. This project has achieved the production process of ursodeoxycholic acid using whole biological enzyme catalysis. The technical characteristics are as follows: mainly using chenodeoxycholic acid as raw material, adding 7a-HSDH oxidase to the NADP circulating enzyme system to achieve the oxidation of the 7-hydroxyl group; Then use the NADP loop enzyme system to add 7 β- HSDH reductase achieves the reduction of ursodeoxycholic acid. This method has the advantages of mild process, safety and environmental protection, fewer side reactions, low production cost, and stable quality.

Process characteristics:

Mainly using chenodeoxycholic acid as raw material, 7a-HSDH oxidase is added to the NADP loop enzyme system to achieve the oxidation of the 7-hydroxyl group, and then the NADP loop enzyme system is used to add the 7-hydroxyl group β- HSDH reductase achieves the reduction of ursodeoxycholic acid. This process realizes the production of ursodeoxycholic acid through whole biological enzyme catalysis. It has the advantages of mild process, safety and environmental protection, few side reactions, low production cost, and stable quality.

Industry analysis:

According to GIR (Global Info Research) research, global revenue for ursodeoxycholic acid was approximately $451.6 million in 2021, and is expected to reach $886.6 million in 2028. The compound annual growth rate (CAGR) from 2022 to 2028 is 10.1%. The core manufacturers of global ursodeoxycholic acid include ICE, Dipharma Francis, Daewoong Chemical, Zhongshan Bailing, and Dipharma Francis. The top five manufacturers hold approximately 70% of the global market share. The global production of ursodeoxycholic acid mainly comes from Europe and East Asia, and they account for about 70% of the market share. The largest market is in the Asia Pacific region, accounting for about 50%, followed by Europe and North America, with market shares of about 31% and 17% respectively. The market demand is increasing year by year, and the industry

中文

中文 English

English

Tel:18805496789

Tel:18805496789